– said no one ever.

Hello friends!

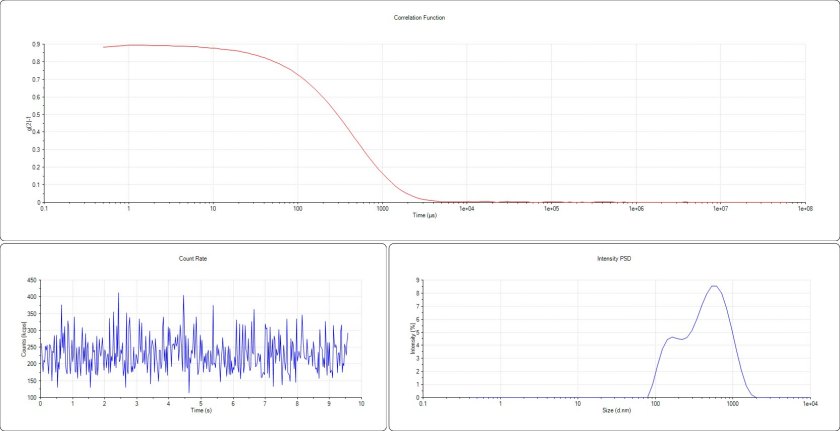

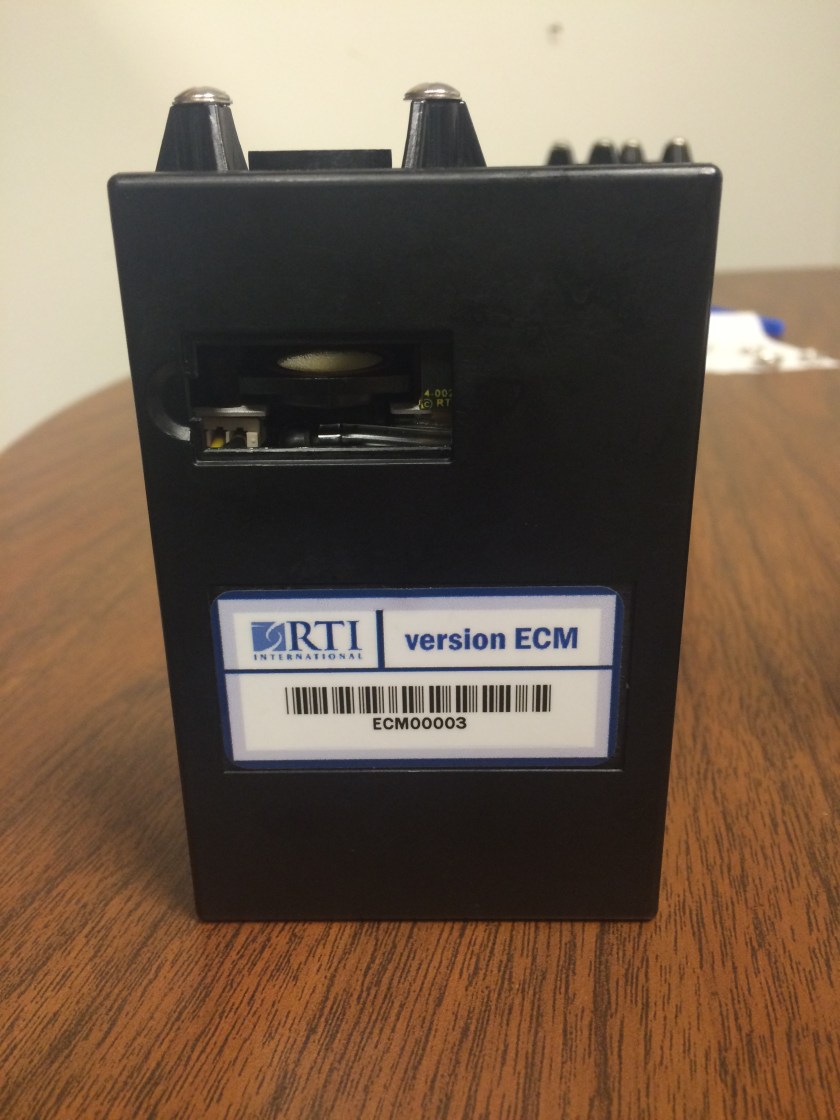

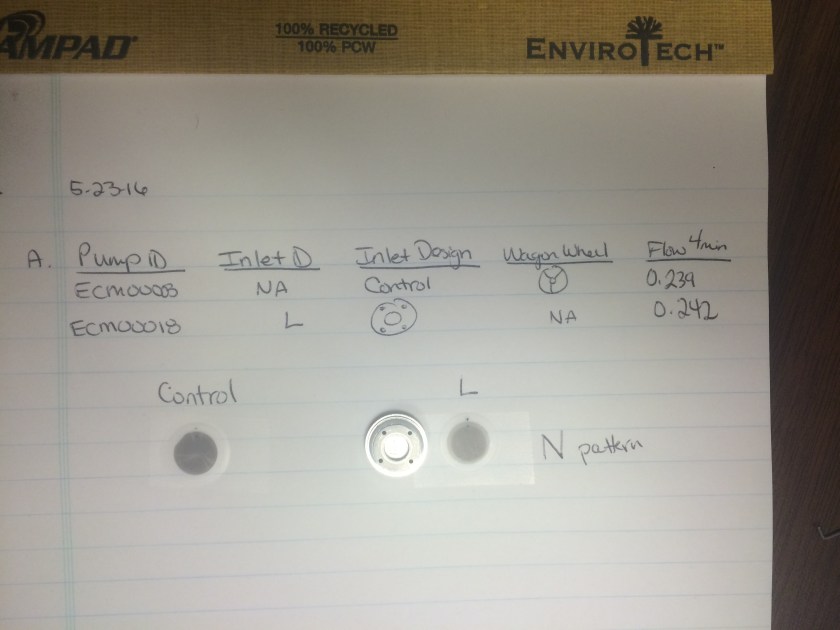

As you may have guessed (or not) from the title, today was mainly focused on testing the EMCs. We started after a quick job receiving and shipping a few items in Bay 3 (or section 3) of the building, and then returned to our normal station in bay 4 to meet with mr. J. Lynn Davis and Andrew Dart to discuss what they do at RTI. I also got to meet up with Emily and her guide, Phillip Durham, who seemed to be a pretty cool dude.

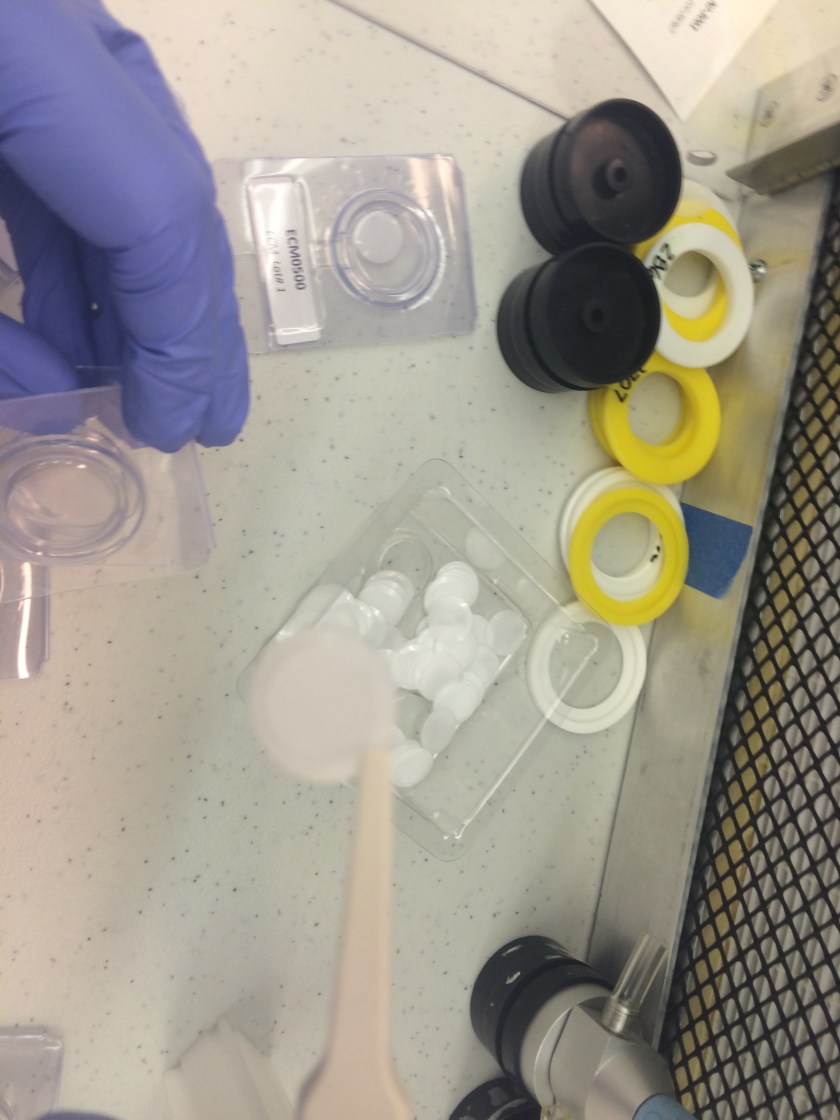

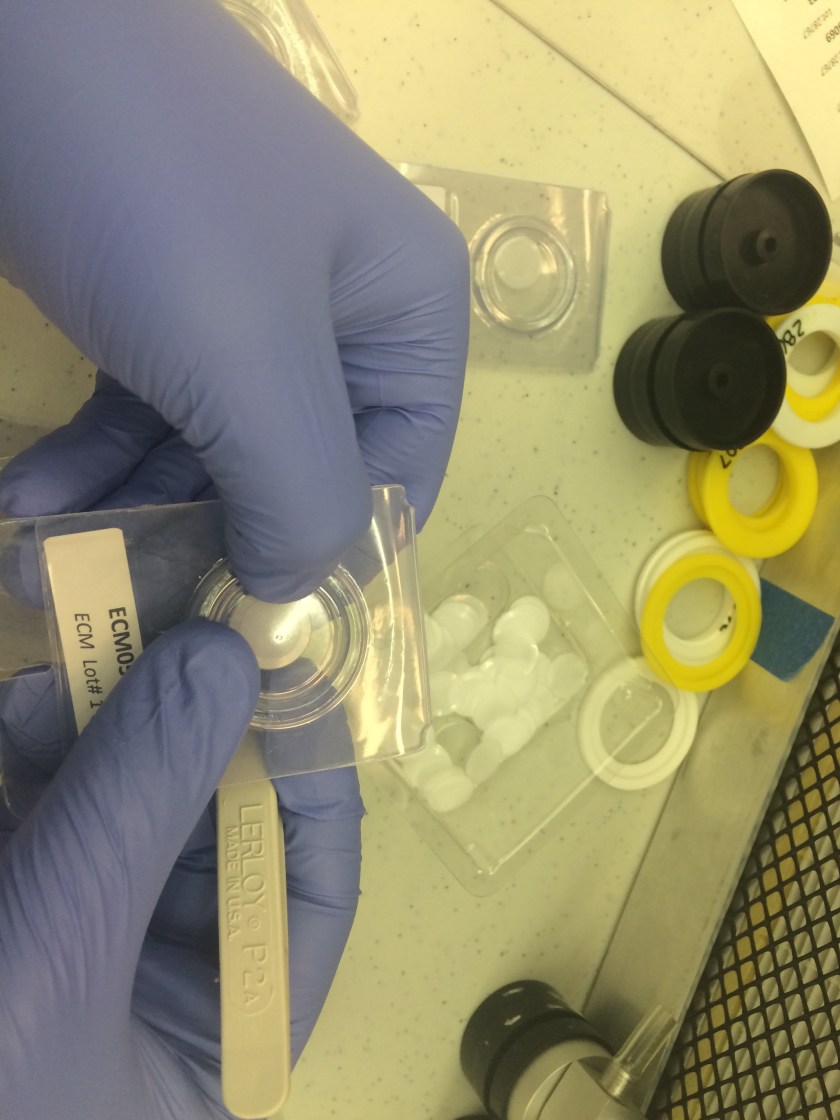

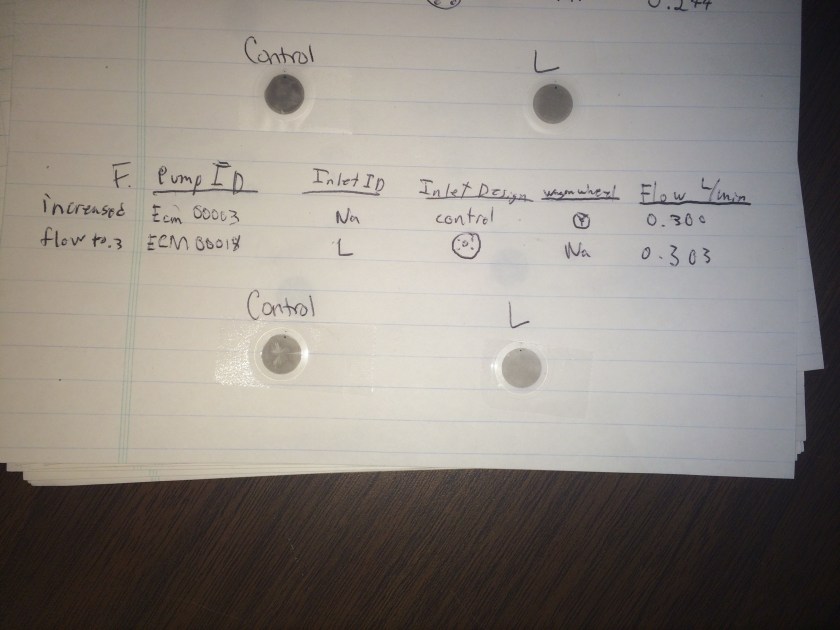

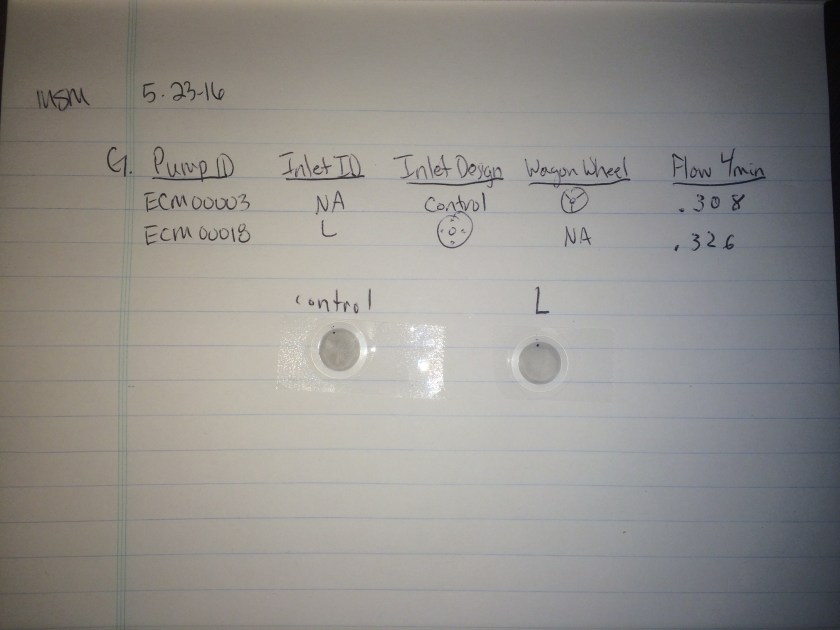

After lunch, we started working with the EMCs again. As the main person testing the filters (with my guide providing aid if needed), I got to light the kerosene lamp needed to produce the black carbon smoke, which was fun. The not so fun part ended up being blowing out the flame, because you get a big whiff of black carbon too. Do you know what that smells like? Imagine eating a box of chalk. It’s roughly the same feeling.

Being the main on that also means you get a lot of black carbon on you as well. Say goodbye to clean hands, folks. That’s a pipe dream.

Anyways, we got through a ton of tests today, and (despite screwing up several tests), we’re almost done with the work. I’ve think I may have gotten the nickname butterfingers at one point… Anyway, we expect to finish tomorrow, so wish us luck, please!

So, without further ado, Butterfingers signing off!