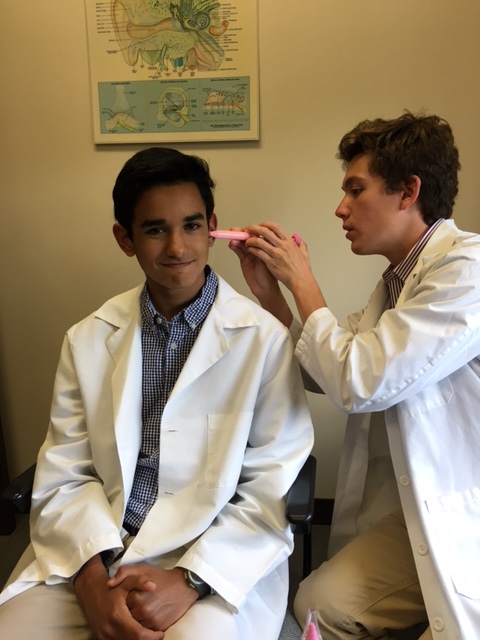

Today was disgusting… all we did was transfer human urine from gallon milk jugs to graduated cylinders to giant containers so that the urine could be filtered and sterilized. Eventually we had transferred and poured 112 liters of pee from place to place. It was utterly gross. Personally, I thought the pee smelled like wet dog food; however, some of the donor’s pee smelled way worse than that. At least we could pass the time and get our minds off of the scent with jokes made by the lab workers. It was reassuring to know that the lab workers weren’t super serious about human urine and could be quite humorous about the subject. It was also very humorous when the lab manager spilled pee all over Jonathan’s lab coat on accident, which down his leg and into his shoe a bit. It was very funny how comfortable they all were dealing with human urine

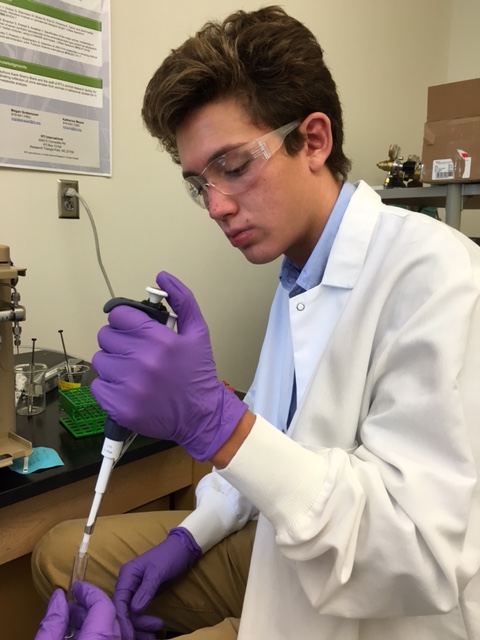

Me pouring urine from a gallon jug to a 4 L graduated cylinder:

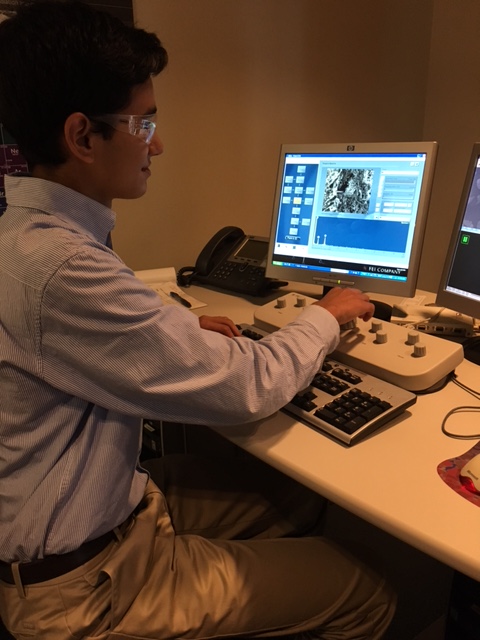

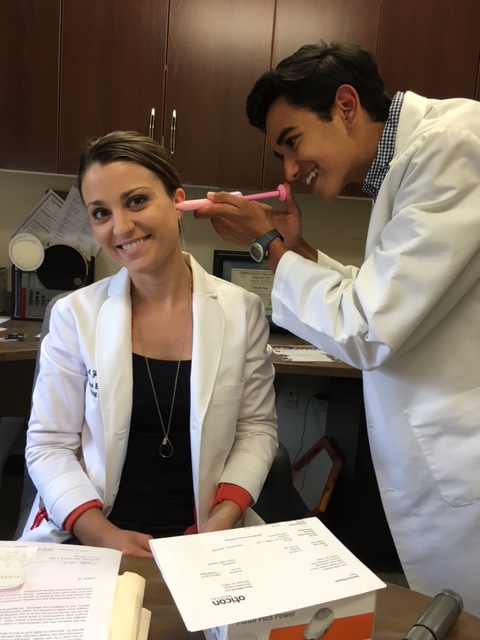

Jonathan pouring urine from the graduated cylinder into the big jug (it is evident from his face that he is not enjoying it):

A total of 112 L of human urine:

I wouldn’t consider today really fun or informative, but I guess it was cool to witness how the dirty work gets done, and how essential it actually is to forensics. I will definitely not take this kind of stuff for granted again! – Kiran W.